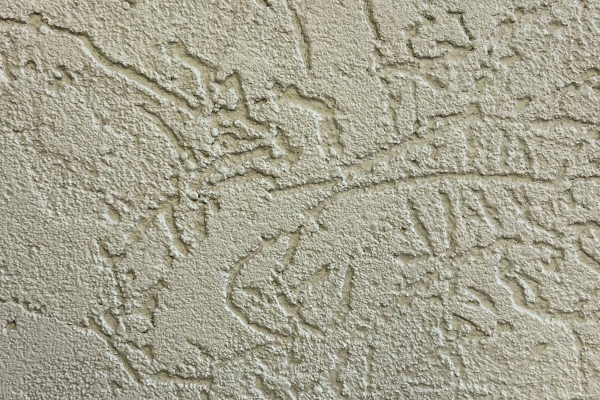

EZYCOAT SCRATCH 2MM

Decorative acrylic texture designed to produce a classic vertical or swirl finish

- Its coarse scratch appearance makes it attractive for use over a variety of fibre cement cladding systems and precast concrete surfaces.

- Suitable for application on clay brick, block, and masonry surfaces.

- Available in Accent Base

| Application Tools | Steel Trowel Plastic Float |

| Sand Grade | Coarse Scratch |

| Coverage | 6 – 10 m2/pail |

| Dry Time (Set Time) ㅤㅤㅤㅤㅤㅤ | Approx. 48 hoursㅤㅤㅤㅤㅤㅤㅤ |

Ezycoat Scratch Render

Ezycoat Scratch Render