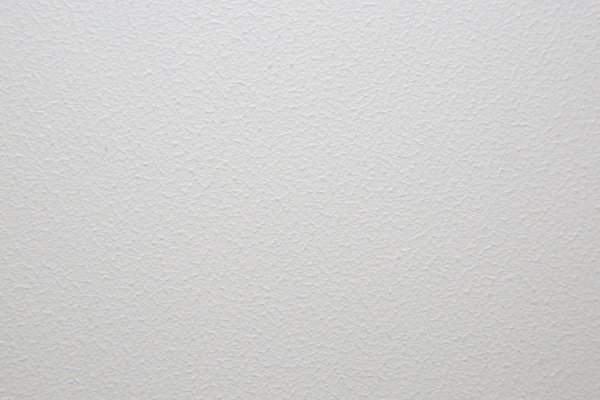

Ezycoat Membrane

Ezycoat Membrane is a hard wearing durable & flexible paint system specifically designed to protect interior and exterior masonry wall surfaces. It has a thicken creamy consistency that when applied allows it to create an extra thick protective coating to the surface.

Using the latest in European technology it has been possible to develop a paint that has excellent adhesion, abrasive resistance and offers the ultimate in protection. The end result is a membrane coating that provides its user with a quality product, with ease of application.

Unlike many external paint finishes that tend to leave roll marks and cut in lines, Ezycoat Membrane when applied to specification will not accentuate these properties; instead provide a seamless finish to the surface.

Ezycoat Membrane

Description: Ezycoat Membrane is a hard wearing durable & flexible paint system specifically designed to protect interior and exterior masonry wall surfaces. It has a thicken creamy consistency that when applied allows it to create an extra thick protective coating to the surface. Using the latest in European, technology it has been possible to develop a paint that has excellent adhesion, abrasive resistance and offers the ultimate in protection. The end result is a membrane coating that provides its user with a quality product, with ease of application.

Surface Application: Suitable for application to Fibre cement sheeting, pre rendered surfaces, AFS, Ritek , Rendered Polystyrene Cladding, Exsulite EPS Cladding, Tilt Concrete & Modakboard* Refer to Technical Data Sheets (TDS). or Ezyspec for application procedures.

Mixing Procedure: Ready to use from the Pail.

Application Method: Ezycoat Membrane is applied by either Brush or Roller. If spraying ensure a suitable tip is used.

Packaging: 15 Lit. Plastic Pails

Coverage: 50 to 60 sqm. per Pail. *Consumption will varying depending on surface to be coated

Ezycoat Membrane Texture

Ezycoat Membrane Texture